You Can Teach An Old Dog New Tricks

Throughout its 160-year history, Crittall Windows has always seen innovation as a source of competitive advantage. Innovation in manufacturing processes, product design, employee welfare, and order processing is behind the continued success of the business.

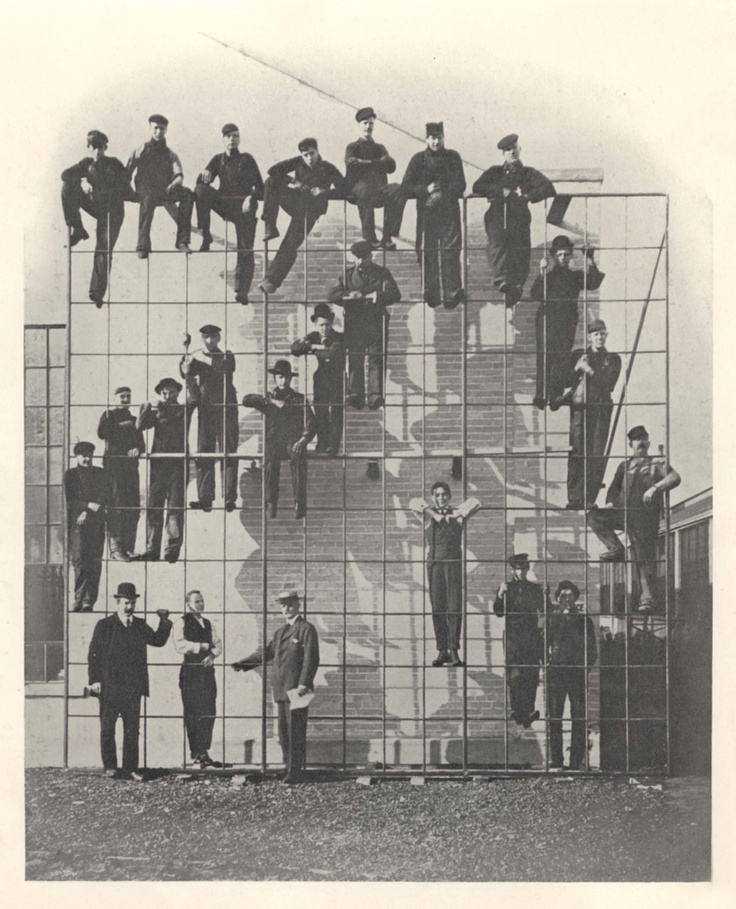

Men of Steel – Crittall workers demonstrating the strength of the Fenestra joint. Try doing that with an aluminium or plastic window

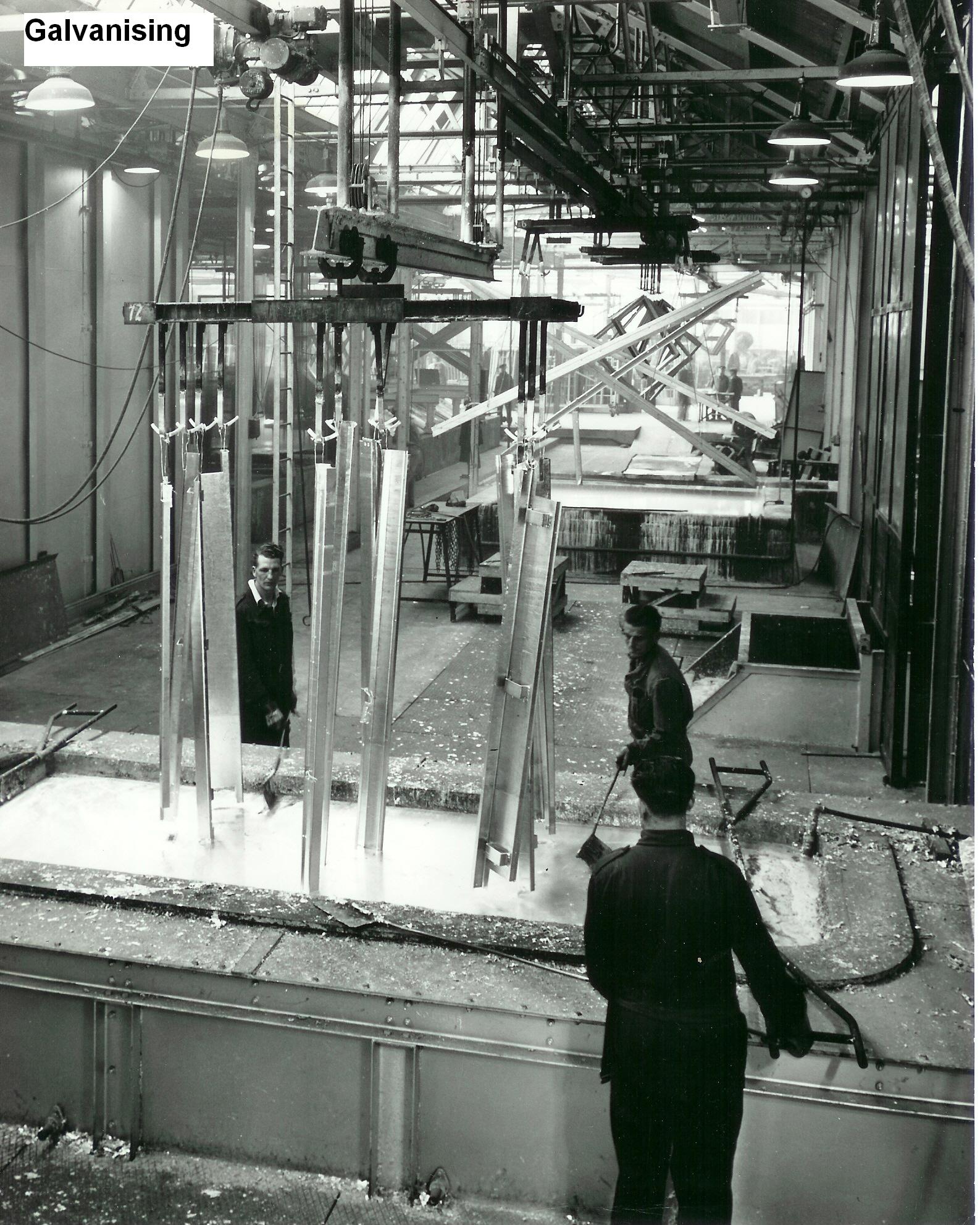

The introduction of the patented fenestra joint, hot-dipped galvanizing for steel frames, the building of Silver End village for its workforce, and the commissioning of the first main-frame computer in Essex are all examples of the company’s innovative approach.

Some of the manufacturing processes owe more to the art of the blacksmith than they do the skill of the engineer, but where possible, Crittall Windows are always looking to improve efficiency, and accuracy by investing in manufacturing technology.

As a 160-year-old company, you can imagine that many of its business processes, are steeped in tradition, their origin lost in the mists of time. Crittall look to realise the benefits of introducing new technology, but also have to recognise that many of the old practices have their place too.

This year, the company invested in a Gianos CNC Machining Centre from leading Italian manufacturers MECAL.

This will boost production efficiency and flexible machining operations across the entire range of products produced at Crittall’s factory in Witham, Essex.

However, sometimes there is no substitute for a skilled craftsman with a good eye, as George Clarke, The Restoration Man, discovered when he tried his hand at Flash Welding.

Reflecting a dual commitment to meet its environmental responsibilities and also dramatically lower its energy costs Crittall has installed a cutting edge Solar Photovoltaic Array onto its main factory roof.

One thousand Solar PV panels will provide a peak rating capability of 250 kWp and the electricity produced will contribute to reducing the overall energy expenditure of the business with all the power generated being consumed during normal production operations. There is also the opportunity to export energy back into the grid during the evenings and weekends.

The £1/4m array, provides, CO2 savings of approximately 140 tonnes per year.

In the same way, the company recognises the need to invest in Information Technology. An example of which is the recent installation of the latest version of an integrated ERP system, Epicor 10, which is interfaced with Klaes. It is able to support the business from identifying an opportunity, through order receipt, design, manufacture, installation and cash collection.

Although there is a CAD system which can improve efficiency and consistency of approach, the company still has designers who prefer to use a drawing board, and, indeed, some customers who are happier to receive designs which have been drawn manually.

The secret of Crittall Windows’ success is to be able to accommodate the traditional approach within its modernisation programme.

You can find out more about genuine Crittall Windows here